At the halfway point of K 2025, the exhibition halls remain packed with visitors, and Haitian International’s booth at Hall 15 / A57 continues to draw strong attention. This year, Haitian Plastics Machinery presents the global debut of the MAV/F PRO high-speed injection molding machine, alongside the Jupiter Series two-platen solution featuring innovative molding technology. Covering both packaging and automotive applications, these two showcases demonstrate a tangible leap in productivity powered by solid technological strength — marking a new rise in efficiency, quality, and sustainability.

Haitian MAV/F PRO Makes Its Global Debut — The High-Efficiency, Energy-Saving Choice for the Packaging Industry

Making its debut at the show, the Haitian MAV/F PRO drew strong attention on site. Building on Haitian’s proven platform, the MAV/F PRO has been newly upgraded for packaging applications—combining high injection speed, superior stability, intelligent control, and energy-saving technology. Balancing performance, precision, and cost efficiency, it delivers a significant boost in productivity and economic return. Designed for thin-wall, multi-cavity, and high-cycle production, it is the ideal solution for maximum output and true High Performance · High Efficiency · High Return.

In the live demonstration, the Haitian MA3800VF/2330PRO turned its technical advantages into a tangible production showcase—producing 130 g PP round containers with a 2-cavity mold in a fast 7-second cycle. Integrated with an automated handling system, the setup ensured smooth and continuous production throughout the show.

This “packaging powerhouse” stands out with four core strengths — Fast, Strong, Stable, and Smart.With an injection speed of up to 800 mm/s, it gives manufacturers a clear edge in high-output, short-cycle production. The FEM-optimized platen structure and V-type toggle design ensure durability and long-term stability for large-volume manufacturing, extending mold life and reducing hidden costs. Equipped with intelligent HT·XTEND functions, it offers a smarter operation and production management experience. Energy savings of up to 30% can be achieved, with specific energy consumption as low as 0.37 kWh/kg — delivering true “high efficiency without high consumption.”

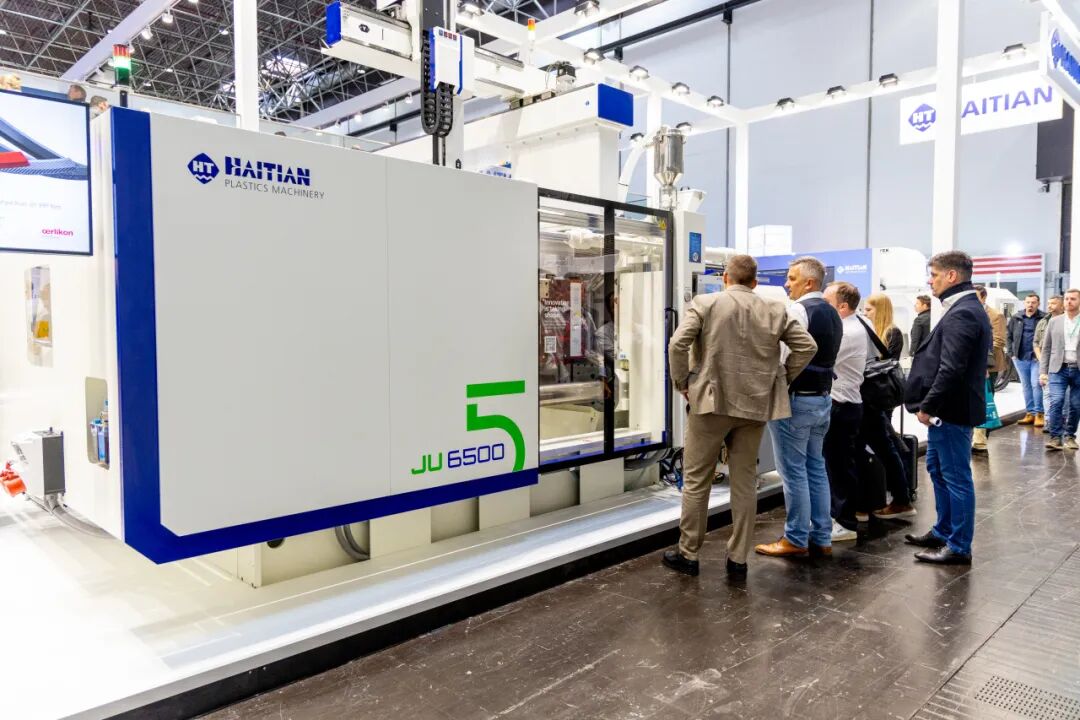

Haitian JU Series Two-Platen Machine Enables One-Step Molding — A Dual Leap in Sustainability and Efficiency

In the live demonstration, the Haitian JU6500V-2250 used recycled polypropylene material and applied paint-free one-step molding technology to produce a 450 g automotive fender component within a 70-second cycle — showcasing a truly green and efficient production process.

In this demonstration, the preformed decorative film was placed directly into the mold and integrally molded with the recycled material during injection — eliminating traditional steps such as transfer, painting, and trimming. The molded parts came out with a high-quality decorative surface that met assembly standards right away — “ready to use out of the mold.” This simplified the production process, significantly improved efficiency, and reduced material waste and cycle time, all while ensuring premium surface quality.

The entire process, from film loading to part removal, was fully automated with Haitian Smart Solutions’ turnkey automation system. It was also equipped with the Go Factory system for real-time production monitoring and management. Meanwhile, the integrated HT·XTEND Inject function continuously optimized the molding process, ensuring stable product quality even when using recycled materials. These innovations present new ideas for sustainable automotive manufacturing, demonstrating the seamless fusion of automotive production and the circular economy.

The Haitian MAV/F PRO delivers a breakthrough in efficiency and cost performance for the packaging industry with its outstanding high-speed capabilities, while the innovative sustainable manufacturing technology of the Haitian Jupiter Series opens new development paths for the automotive sector. These two showcases represent not only a display of technology but also Haitian’s active exploration of future smart manufacturing models.

K 2025 continues until October 15 — Haitian International warmly welcomes all visitors to Hall 15 / A57 to explore the future of injection molding technology and join us in advancing the industry toward greater efficiency, sustainability, and green manufacturing.