In Kocaeli, Turkey’s major industrial center, automotive and electrical component manufacturer Shinko is entering a new phase of rapid capacity expansion. With uncompromising standards for production stability, molding precision, and overall line efficiency, any weak link could jeopardize customer delivery commitments. As orders surged in early 2024, Shinko’s production bottlenecks became increasingly evident, driving the company to seek high-efficiency, high-precision, and high-quality injection molding solutions.

When evaluating the global market, Shinko’s expectations were clear: they needed equipment capable of sustaining high-load precision molding, and a partner who understands their industry and can provide long-term, reliable support. This set the stage for their cooperation with Haitian International.

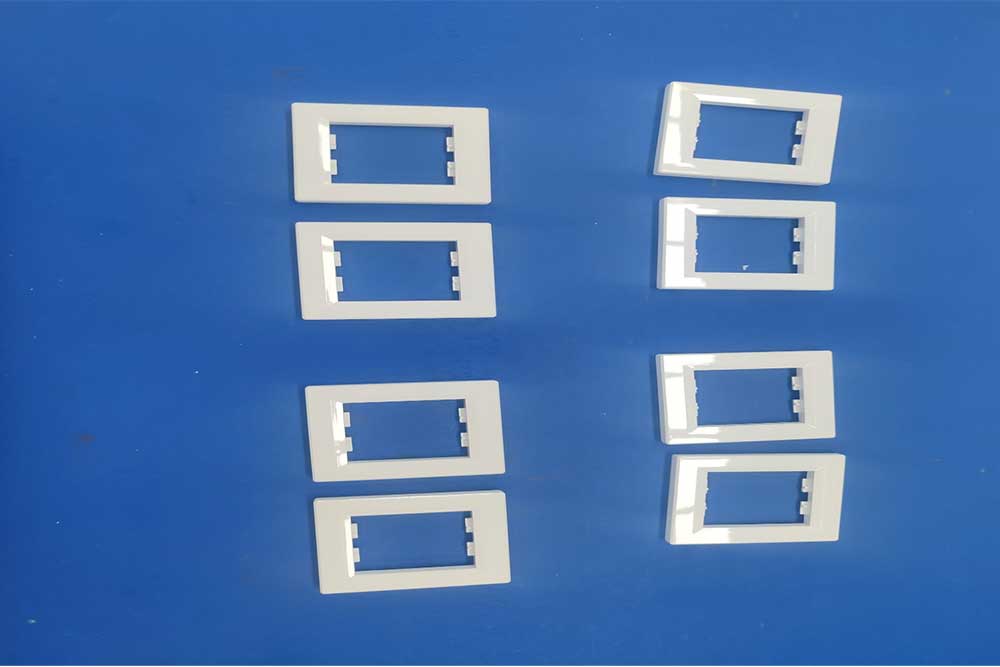

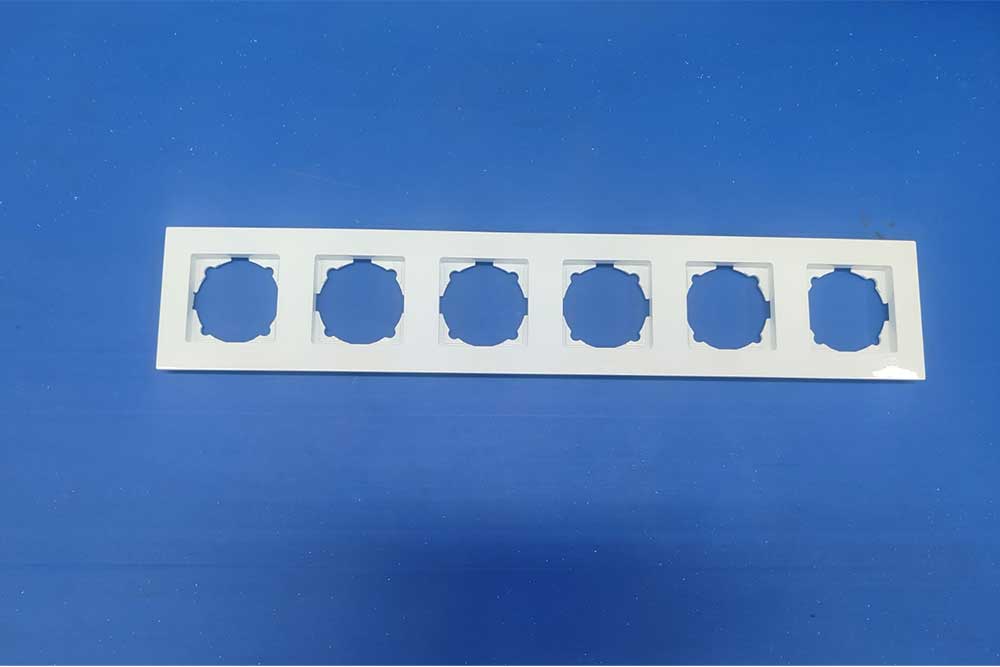

After a detailed assessment of Shinko’s production pain points, Haitian International delivered a tailored solution centered on the Haitian MAV Series servo injection molding machines:

The high-response servo system became the core of Shinko’s production floor, reducing energy use while keeping cycle times stable enough to meet strict automotive standards. The integrated control system ensured smooth coordination between machines and robots, raising automation and reducing manual errors. Shinko also valued Haitian’s strong local service presence. With a technical service center in Turkey, Haitian provides 24-hour response and continuous process optimization to keep the equipment running at its best. For Shinko, this represents more than after-sales support—it is a long-term commitment to production stability.

After multiple rounds of testing, Shinko confirmed Haitian’s advantages in precision, energy efficiency, and overall reliability. As the General Manager noted, Haitian delivered not just machines but a solution that can grow with the company.

All 16 Haitian injection molding machines purchased by Shinko have now been installed, commissioned, and put into stable operation on the company’s automotive and electrical component lines. Real production data has validated the choice, with overall efficiency increasing by approximately 22% and defect rates dropping to below 0.3%.

According to Shinko’s Procurement Director, this collaboration marks not simply an equipment purchase but the beginning of a long-term strategic partnership, with both sides expecting deeper cooperation in future expansion plans. This trust reflects Haitian International’s commitment to globalization through localized value creation.

In Shinko’s production workshop, each steadily running Haitian machine highlights the value of localized service. Through advanced technology and strong local support, Haitian helps manufacturers enhance their operations with reliable quality and timely service, enabling its solutions to integrate seamlessly into the local industrial ecosystem and deliver lasting value. As Shinko grows, Haitian will continue providing solutions tailored to local needs, supporting shared development and long-term success.