On November 19, 2025, Indonesia’s largest plastics industry event — Plastic & Rubber Indonesia — opened grandly at the Jakarta International Expo. Haitian International is exhibiting at Hall C3, Booth No. 7618.

As Indonesia continues to advance its local manufacturing protection policies, the injection molding sector is entering a stage of both opportunity and intensified competition. The show has also drawn many machinery manufacturers making their first move into the Indonesian market.

As a key exhibitor at this year’s event, Haitian International took center stage with a prime position at the main entrance of Hall C3. With an 8 × 21 m booth — the largest in the hall — the company became a major highlight of the exhibition. Haitian International showcased three innovative machine models and, together with Haitian Precision, presented a CNC machining center, demonstrating the strong manufacturing capabilities of the Haitian Machinery portfolio in advanced equipment processing.

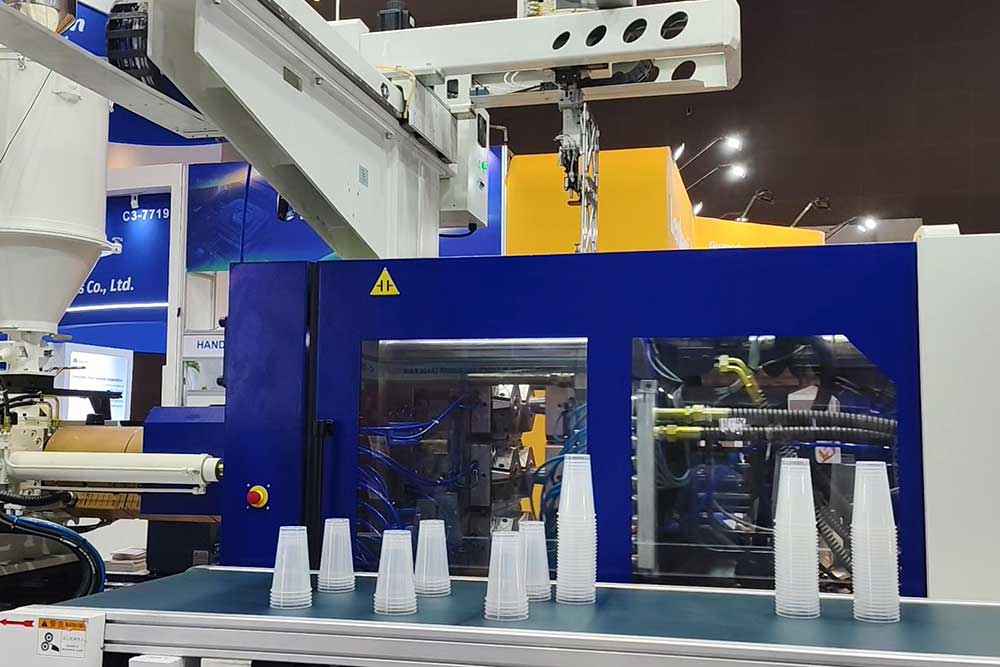

At the show, the Haitian MA3800H/1280PRO injection molding machine demonstrated the production of 1×6 500 ml bubble tea cups. The setup used a custom MFI = 60 PP material developed by Haitian Tongchuang specifically for bubble-tea cups, paired with the Haitian Smart Solutions high-speed, high-rigidity robot VS1100-ID.

The Haitian MA1600M/570-E400 highlighted the production of 1×1 two-color PC drinking cups. The setup combined a Lingyi patented blow-molding system with Haitian’s self-developed second-generation color-powder dosing unit, integrated with the Haitian Smart Solutions “three-in-one” system and an in-house servo robot. Together, these ensure a stable and efficient production cycle while expanding application possibilities for single-color molds, enabling everyday consumer goods molds to achieve richer color variations.

Niigata’s MD100S8000 all-electric injection molding machine demonstrated the production of 1×4 cavity electrical folding connectors, using pure PA66 and paired with a Haitian Smart Solutions five-axis servo robot. Its core strengths lie in high precision, strong stability, and excellent process adaptability.

The machine’s high-precision structural design ensures dimensional stability for thin-wall and precision parts; dynamic holding-pressure and clamping-force control guarantee consistency for thick-wall molding. Dual-screw injection and advanced temperature-control reduce material-plastication fluctuation and lower defect rates. Ultra-low-speed injection and anti-drool functions address the key challenges of thick-wall transparent parts, improving yield. Independent-motor linkage supports efficient production while meeting flexible manufacturing needs, ensuring smooth transition from trial runs to mass production for high-quality parts.

In addition, Haitian Precision’s V8 CNC machining center — a top-selling model in Southeast Asia — fully meets customer needs in mold repair and machining. As the only machining center on display across the entire venue, it drew considerable attention from visitors, showcasing Haitian Machinery’s ability to provide customers with comprehensive “from production to factory maintenance” solutions.

Looking ahead to 2026, Haitian International will continue to deepen its presence in Indonesia and introduce advanced solutions tailored to local needs. Anchored in high-quality products and services, we aim not only to meet customers’ immediate production requirements but also to drive the rapid upgrading and long-term development of Indonesia’s injection molding industry — supporting the growth and competitiveness of local manufacturers in a practical and sustained way.